Introdution:Why ITO Conductive Matters Today?

In today's smart technology era, touch control has become the primary way people interact with devices, influencing almost every aspect of daily life. From smartphones and tablets to in-car navigation systems, touch interfaces are now an essential part of modern electronics. At the heart of these touch panels is ITO conductive glass, a material that stands out for its unique combination of high transparency and excellent conductivity, making it indispensable in a wide range of electronic products. This material is driving human-machine interaction toward higher sensitivity and greater reliability. In this article, we’ll take a closer look at the technical features and application value of ITO-coated glass, giving you a clear understanding of why it plays such a vital role in the touch technology industry.

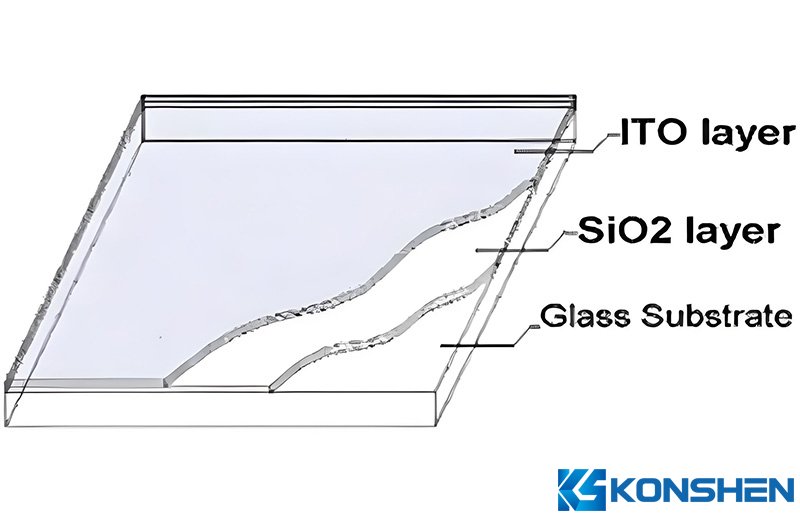

ITO (Indium Tin Oxide) conductive glass is a functional material made by depositing a transparent conductive oxide film onto an ultra-thin glass substrate using advanced coating technology. This unique composite structure gives it the dual properties of glass's light transmission and metal’s electrical conductivity.

Based on differences in sheet resistance and optical performance, ITO conductive glass is generally classified into three main categories:

One of the most notable advantages of ITO conductive glass lies in its superior optical properties. In the visible light spectrum, its transmittance typically remains above 80%, and high-end products treated with AR (anti-reflective) coating can achieve up to 92% light transmittance, with almost no impact on display quality. This excellent transparency ensures clear visuals and accurate color reproduction, allowing image details to be rendered authentically with vibrant, lifelike colors.

ITO glass demonstrates excellent electrical conductivity thanks to precisely controlled coating processes. Sheet resistance uniformity can be maintained within ±10%, ensuring consistent performance across the entire surface. More importantly, this conductivity remains stable under various environmental conditions, which is critical for accurate touch signal transmission. Whether in dry winter air or humid rainy seasons, ITO glass delivers a reliable and smooth touch experience.

Mechanically, ITO conductive glass offers outstanding surface hardness and abrasion resistance, with hardness levels reaching above 6H. It can withstand everyday friction and scratches while maintaining its conductive properties. When strengthened through tempering or chemical treatment, it becomes highly resistant to accidental drops and impacts, significantly extending the lifespan of the product.

Environmental durability is another key advantage that makes ITO glass ideal for touch panel applications. It operates reliably across a wide temperature range of -30°C to 85°C and exhibits strong resistance to humidity fluctuations and common chemical substances. This adaptability enables it to perform consistently in various challenging environments—from freezing outdoor conditions to high-temperature automotive interiors, and from humid bathrooms to dry desert climates. It's important to note that -30°C to 85°C is not the absolute limit for ITO glass. The actual threshold depends on factors such as substrate material, ITO film thickness, and annealing process. High-reliability products can easily exceed this range, and with additional specialized processing, ITO glass can even meet the extreme temperature requirements of military, aerospace, or industrial heating applications.

The conductive mechanism of ITO films originates from their unique crystalline structure, which is a carefully engineered semiconductor material. When some indium ions are replaced by tin ions, free electrons are generated, giving the material n-type semiconductor characteristics. This special doping process allows ITO to maintain high transparency while achieving excellent electrical conductivity.

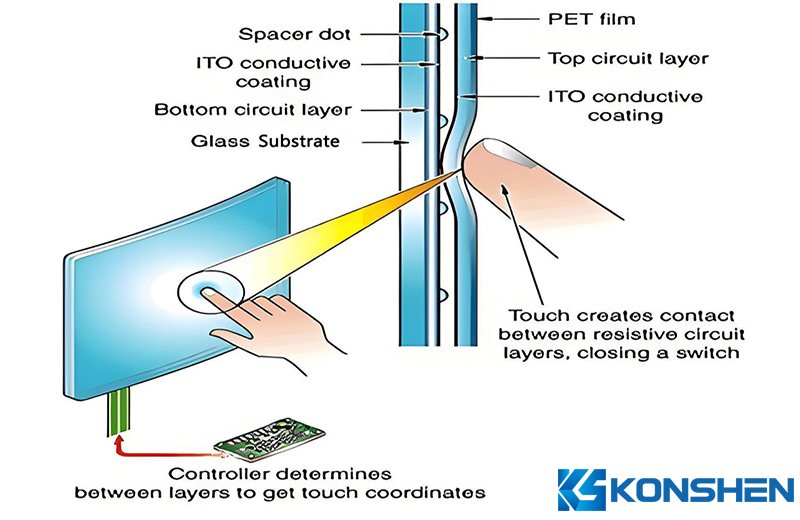

In practical touch applications, the ITO layer functions as a sensing electrode that forms a uniform electrostatic field across the entire touch surface, laying the foundation for accurate touch detection. When a finger touches the surface, it alters the local capacitance distribution. Although this change is extremely small, it is significant enough to be captured by highly sensitive detection circuits.

The controller then analyzes these tiny capacitance variations to accurately determine the touch location, processes the signals using advanced algorithms, and sends the results to the processor for command execution. All these complex steps are completed within milliseconds, enabling fast and precise human-machine interaction.

Modern ITO touch technology can recognize multiple touch points simultaneously, supporting complex gesture operations and delivering a smooth, intuitive user experience.

The production of ITO conductive glass begins with a meticulous cleaning process, which is the critical first step to ensure product quality. Multiple ultrasonic cleaning stages combined with plasma cleaning are employed to thoroughly remove any contaminants and microscopic particles from the glass surface. This guarantees an ultra-clean substrate surface, creating ideal conditions for the subsequent coating process.

The core coating step—magnetron sputtering—is performed in a highly controlled vacuum environment. Several key parameters, including vacuum level, gas composition, and substrate temperature, must be precisely regulated. By carefully adjusting sputtering power and substrate temperature, a uniform ITO thin film is deposited onto the glass surface. The film thickness, typically ranging from several tens to a few hundred nanometers, must be maintained within a very narrow tolerance range. After sputtering, a thermal annealing process is carried out in a protective atmosphere to optimize the film’s crystalline structure and electrical properties. This annealing step is critical, as it directly determines the final performance of the product.

Stringent quality control runs through the entire production process, covering optical performance, electrical parameters, and surface appearance.

In the consumer electronics sector, ITO conductive glass has become a standard component for touch-enabled devices such as smartphones and tablets. With the continuous advancement of display technology—larger screens and higher resolutions—the performance requirements for ITO glass have grown significantly. Low-resistance products are especially suitable for applications demanding large screen sizes and high sensitivity, such as premium smartphones and high-end tablets. These devices require ITO glass to maintain high transparency while offering lower resistance for fast response and precise touch detection. Additionally, ITO glass can be combined with AF (anti-fingerprint) and AR (anti-reflective) coatings to enhance usability by reducing smudges and glare.

Automotive display systems impose stricter demands on ITO glass, including wide operating temperature ranges, anti-glare properties, and long-term durability. Automotive environments can experience temperature variations exceeding 70°C—from freezing winters to scorching summers—making thermal stability essential. Advanced ITO coating technologies address these challenges by optimizing target materials, layer thickness, and deposition parameters to ensure stable performance under all conditions. For head-up displays (HUDs), ITO glass requires extremely high transmittance and optical clarity. A combination of ITO and AG (anti-glare) coatings can simultaneously meet touch requirements and reduce reflections from strong light, improving driving safety and visual comfort.

Industrial control devices demand more robust ITO glass solutions, incorporating features such as explosion resistance and scratch protection. These systems often operate in harsh environments with exposure to vibration, oil, and chemical corrosion. Industrial-grade ITO glass can be enhanced with thicker coatings and AS (anti-scratch) layers to achieve surface hardness up to 9H, ensuring superior durability. For medical equipment, ITO glass must meet stringent hygiene requirements. Incorporating AB (antibacterial) coatings effectively inhibits bacterial growth, making it suitable for hospital environments.

Smart home devices prioritize both functionality and aesthetics, making ITO glass an ideal choice. From smart refrigerators and mirrors to control panels and intelligent switches, ITO glass offers a sleek, modern appearance while ensuring reliable touch performance. Surface treatments such as AF coatings add fingerprint resistance and reduce interference, allowing ITO glass products to seamlessly integrate into various home environments—providing a balance of practicality and elegance.

ITO conductive glass plays an irreplaceable role in touch technology, combining transparency, conductivity, and durability. From consumer electronics to automotive displays and industrial interfaces, its application scope continues to expand in parallel with global digitalization. Understanding the characteristics, manufacturing processes, and application areas of ITO glass helps engineers select the most suitable solution for their projects—precisely the purpose of this article. As manufacturing technology and material science continue to evolve, ITO glass will remain at the forefront of interactive display technology, shaping the future of smart devices and human-machine interaction.

For more technical details, feel free to contact the KS Glass technical team—we are committed to providing you with professional products and services.

Ready to take your glass project to the next level? Contact us today to discuss your custom glass needs and get a quote!

contact us